Цифровая полка под контролем. Выводите товары до 50 раз быстрее

Экосистема для работы с данными о товарах. Полный контроль над контентом и статистикой

Решения для вашего бизнеса

“С помощью Brandquad мы эффективнее работаем с продуктовым контентом, а также получаем доступ к точной и подробной аналитике. В результате работа, которая раньше могла растянуться на недели, теперь занимает считанные часы.”

«Мы уверены, что внедрение технологий и автоматизация максимального числа процессов помогут сделать планирование более точным, а также снизят риски и издержки от ошибок, которые допускаются при работе с данными вручную. Мы нацелены создать лучший Service Level в том числе для иностранных партнеров»

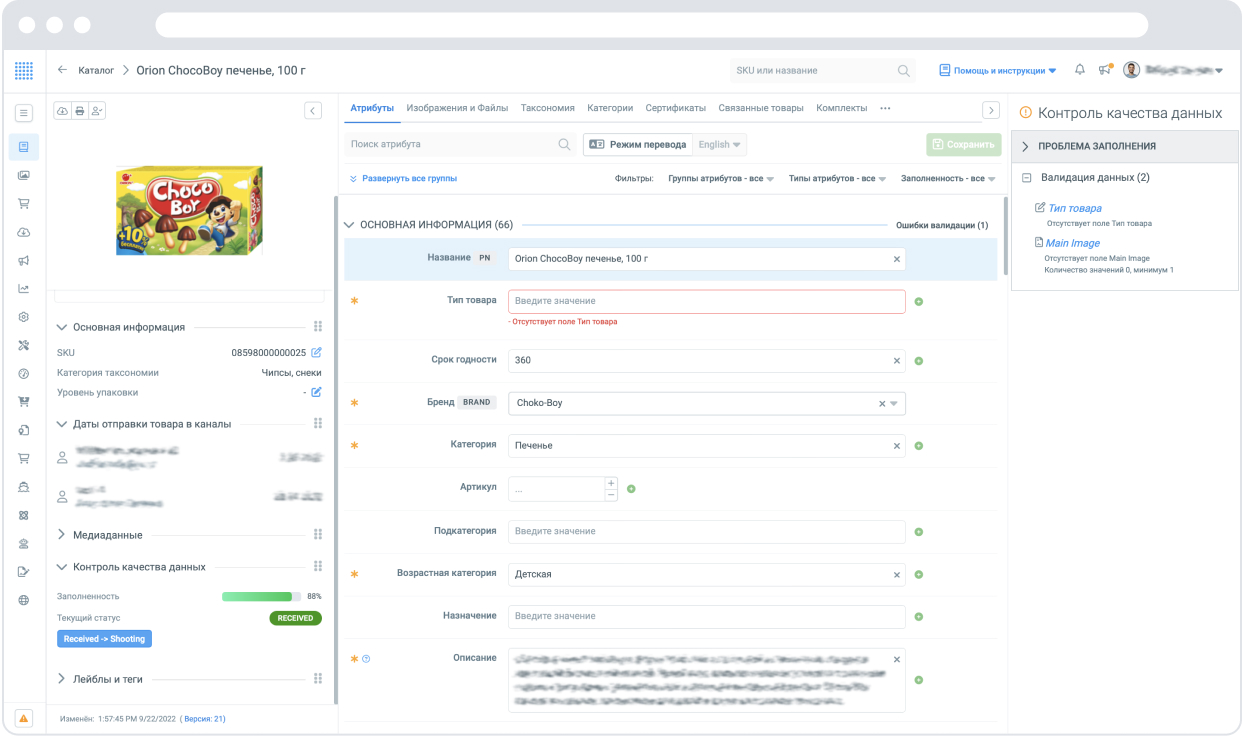

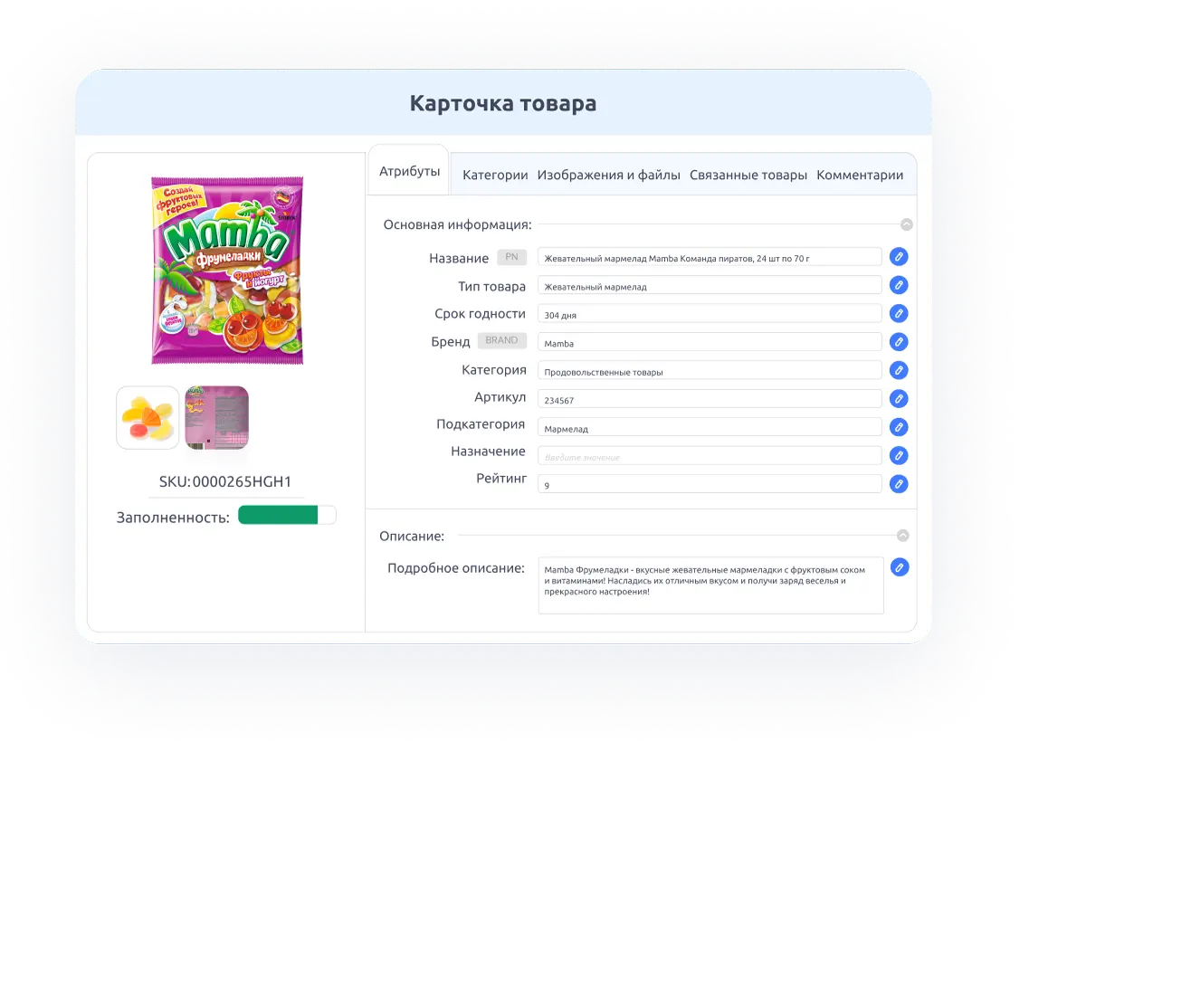

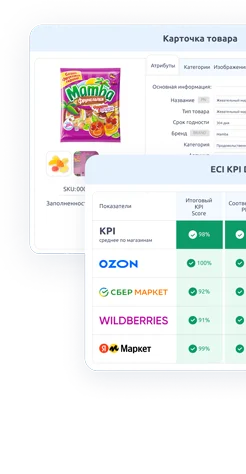

сократите отказы из-за ошибок

быстрее выгружайте готовые данные ритейлерам

сокращайте время заполнения карточки товара

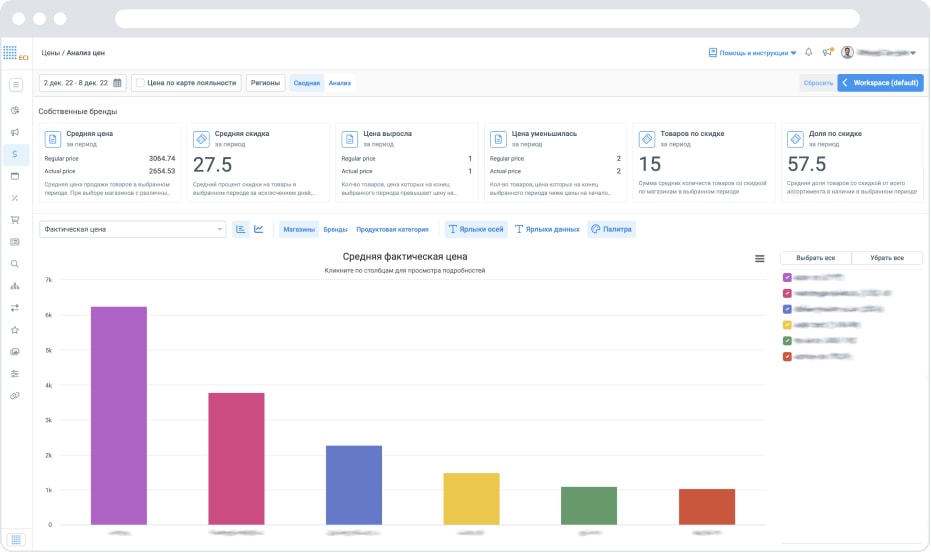

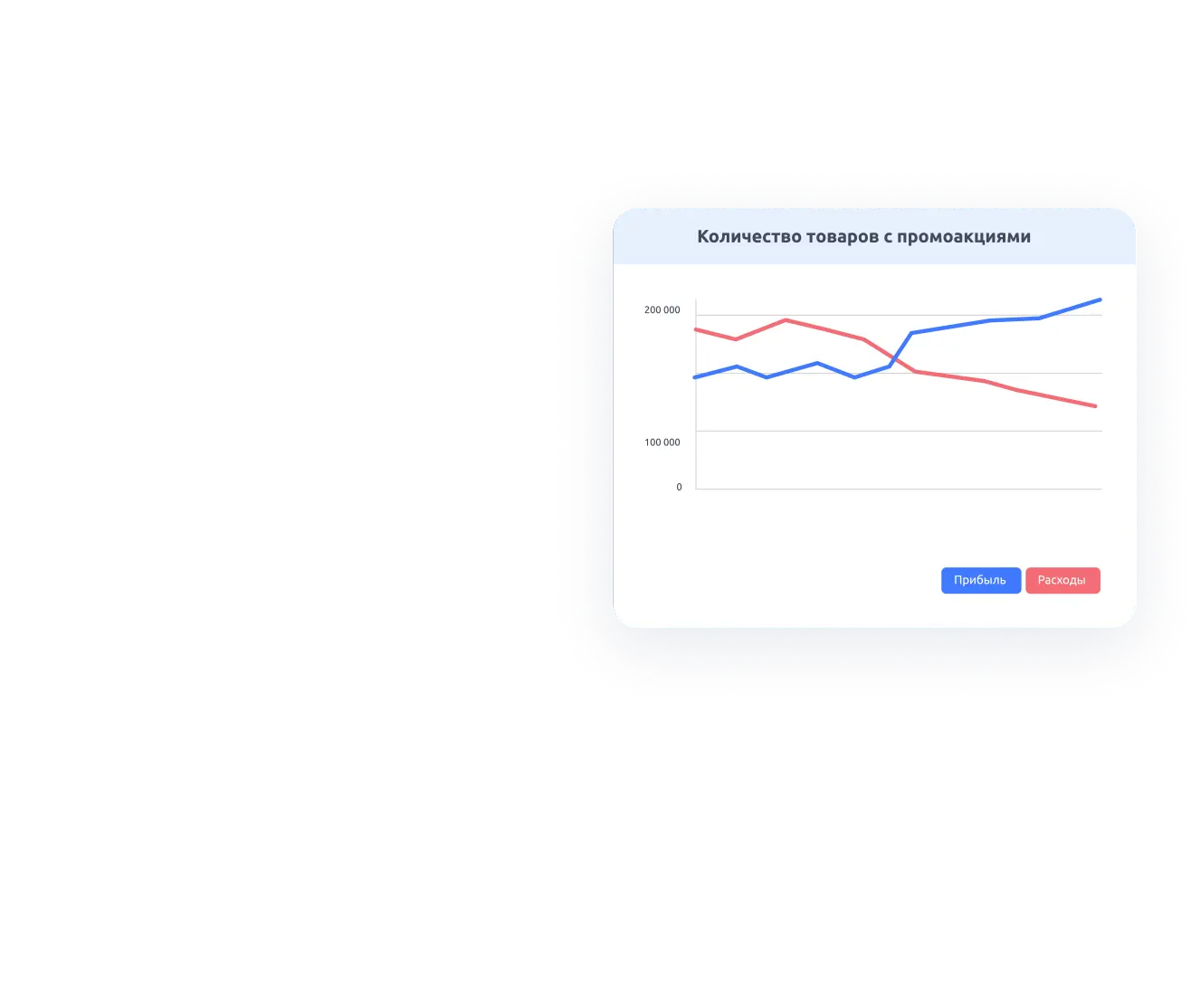

оптимизируйте e-com

и получайте ROI